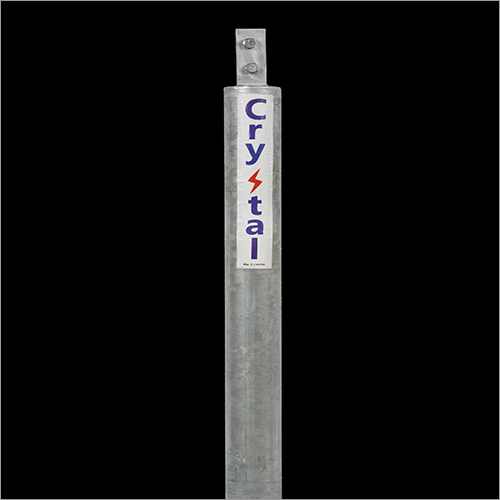

GALVANIZED EARTHING ELECTRODE

Product Details:

- Strength NA

- Diameter 48MM Millimeter (mm)

- Life Span 20 YEARS OF SAFETY

- Purity 99%

- Product Type EARTHING

- Material Galvanized Steel

- Application Earthing

- Click to View more

GALVANIZED EARTHING ELECTRODE Price And Quantity

- 1 Set

- 1500.00 INR/Kit

- 1500.00 - 12000.00 INR/Kit

GALVANIZED EARTHING ELECTRODE Product Specifications

- GALVENIZED

- Galvanized Steel

- 48MM Millimeter (mm)

- ROUND

- 18 KG Kilograms (kg)

- 48MM *3 MTR Meter (m)

- NA

- 99%

- SILVER

- 1 YEAR

- EARTHING

- EARTHING SAFETY

- 20 YEARS OF SAFETY

- Earthing

GALVANIZED EARTHING ELECTRODE Trade Information

- nahvasehva /hazira

- 300 Set Per Day

- 3 Days

- BUBBLE PACKING

Product Description

A galvanized earthing electrode is a type of grounding component used in electrical systems to provide a safe path for fault currents to dissipate into the earth It is typically made of steel or iron and coated with a layer of zinc through a process called galvanization This zinc coating protects the electrode from corrosion ensuring its longevity and effectiveness in various soil conditions

Key Features of Galvanized Earthing Electrodes

1 Material Usually made of mild steel or iron

2 Galvanization Coated with zinc to prevent rust and corrosion

3 Durability Suitable for longterm use in different soil types

4 Conductivity Provides a lowresistance path for electrical currents to flow into the ground

5 CostEffective Generally more affordable compared to copper electrodes

Applications

Electrical grounding systems for buildings substations and industrial plants

Lightning protection systems

Telecommunication towers and equipment grounding

Renewable energy systems solar and wind farms

Advantages

Corrosion Resistance The zinc coating protects the electrode from soil moisture and chemicals

Strength Steel or iron provides mechanical strength making it suitable for driving into the ground

CostEfficiency Cheaper than copper while still providing effective grounding

Disadvantages

Lower Conductivity Compared to copper galvanized steel has higher resistance which may require larger or multiple electrodes for effective grounding

Limited Lifespan in Highly Corrosive Soils In extremely corrosive environments the zinc coating may degrade over time

Installation

The electrode is driven vertically into the ground to a depth where it can maintain good contact with the soil

It is connected to the electrical system using a grounding conductor

Regular maintenance and testing are recommended to ensure proper functioning

Standards and Specifications

Galvanized earthing electrodes must comply with international and local standards such as

IEEE 80 Guide for Safety in AC Substation Grounding

IEC 62305 Standards for lightning protection

IS 3043 Indian Standard for Code of Practice for Earthing

In summary galvanized earthing electrodes are a reliable and costeffective solution for grounding systems especially in areas where soil conditions are not highly corrosive However in environments with high corrosion risk copperbonded or solid copper electrodes may be preferred

FAQs of GALVANIZED EARTHING ELECTRODE:

Q: What is the material used for the GALVANIZED EARTHING ELECTRODE?

A: The GALVANIZED EARTHING ELECTRODE is made of galvanized steel.Q: What is the diameter of this earthing electrode?

A: The diameter of the GALVANIZED EARTHING ELECTRODE is 48 mm.Q: What is the life span of the GALVANIZED EARTHING ELECTRODE?

A: The GALVANIZED EARTHING ELECTRODE has a life span of 20 years of safety.Q: What are the dimensions of the GALVANIZED EARTHING ELECTRODE?

A: The dimensions of the GALVANIZED EARTHING ELECTRODE are 48 mm by 3 meters (L*W*H).Q: What is the warranty period for the GALVANIZED EARTHING ELECTRODE?

A: The GALVANIZED EARTHING ELECTRODE comes with a warranty of 1 year.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS